Publications

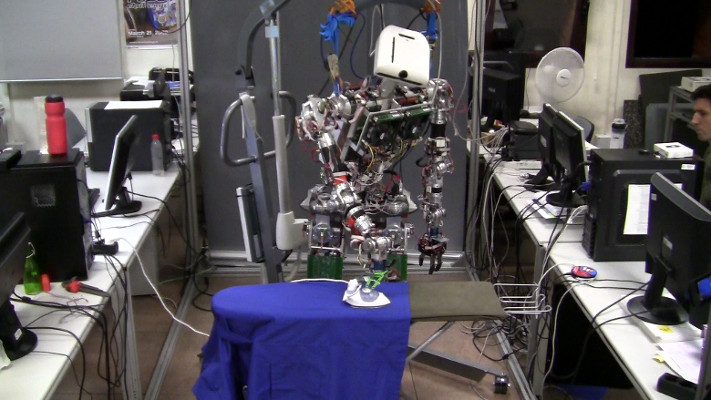

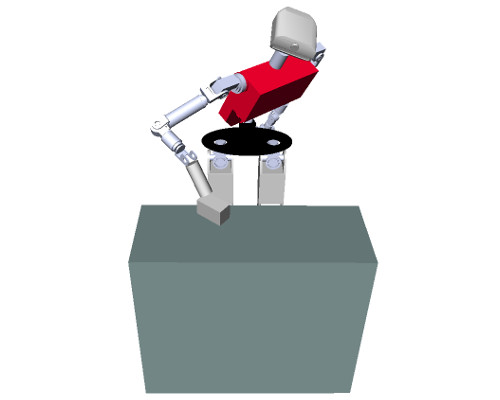

Robotic Ironing with 3D Perception and Force/Torque Feedback in Household Environments

David Estevez, Raul Fernandez-Fernandez, Juan G. Victores, Carlos Balaguer

Abstract

As robotic systems become more popular in household environments, the complexity of required tasks also increases. In this work we focus on a domestic chore deemed dull by a majority of the population, the task of ironing. The presented algorithm improves on the limited number of previous works by joining 3D perception with force/torque sensing, with emphasis on finding a practical solution with a feasible implementation in a domestic setting. Our algorithm obtains a point cloud representation of the working environment. From this point cloud, the garment is segmented and a custom Wrinkleness Local Descriptor (WiLD) is computed to determine the location of the present wrinkles. Using this descriptor, the most suitable ironing path is computed and, based on it, the manipulation algorithm performs the force-controlled ironing operation. Experiments have been performed with a humanoid robot platform, proving that our algorithm is able to detect successfully wrinkles present in garments and iteratively reduce the wrinkleness using an unmodified iron.

[arXiv] [bibtex] [source code]

Robotic Ironing With a Humanoid Robot Using Human Tools

David Estevez, Raul Fernandez-Fernandez, Juan G. Victores, Carlos Balaguer

Abstract

There is an increasing demand of robots able to assist people in everyday home tasks. Some of these tasks, specially garment-related tasks (e.g. laundry, ironing, etc), are currently a big challenge for robots due to deformations and the high number of possible configurations the garment can adopt. Ironing, additionally, requires manipulation and control of the iron, as if performed incorrectly it can create even more wrinkles. In this work we present a method for robotic ironing with an unmodified iron and ironing board and a full-body humanoid robot, inspired in the way people perform the ironing task. In this method, the robot performs an ironing action controlled in velocity with feedback from a force/torque sensor. This action is later analyzed by the robot using computer vision to determine if any wrinkle exists, either pre-existent or created by the ironing action. The 3D vision algorithm segments the garment surface to be ironed and computes a Wrinkleness Local Descriptor (WiLD) that determines the location of the wrinkles on the garment. Wrinkles are processed using computer vision techniques on an flattened image created from the WiLD descriptors computed in the prior stage, resulting, if present, in an optimal ironing path that reduces wrinkleness and avoids creating new wrinkles in garments when ironing. The experimental results show that using our method the humanoid robot is able to successfully iron several garments with results similar to the expected from a human performing the same task.

[paper] [slides] [bibtex] [source code]